- Home Page

- Company Profile

-

Our Products

- Gate Valve

- Ball Valve

- Strainer Valve

- Air Valve

- Globe Valve

- Safety Valve

- Control Valve

- Dual Plate Check Valves

- Pulp Valve

- Plug Valve

- Pinch Valve

- EPDM Diaphragm Valves

- Needle Valve

- Foot Valve

- Piston Valve

- Diaphragm Valve

- Cast Steel Gate Valve

- Brass Ball Valve

- Cast Iron Valves

- SS Ball Valve

- Solenoid Valve

- Check Valve

- Knife Edge Gate Valve

- Valves

- Cast Iron Butterfly Valve

- Butterfly Valve

- Contact Us

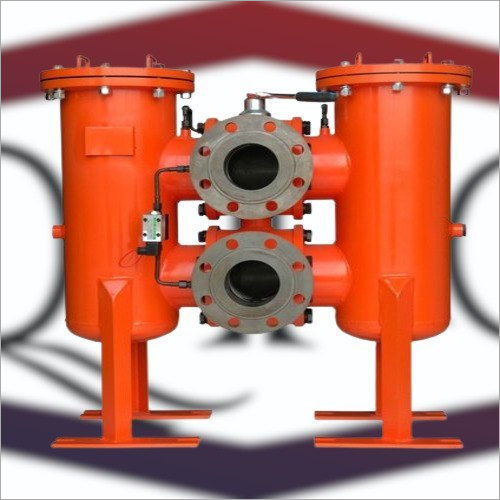

Duplex Strainer Valves

6500 INR/Piece

Product Details:

- Application Industrial

- Structure Other

- Type Strainer Valve

- Pressure High Pressure Pa

- Product Type Valve

- Media Water, Gas, Oil, Acid, Base

- Color Orange

- Click to View more

X

Duplex Strainer Valves Price And Quantity

- 1 Piece

- 6500 INR/Piece

Duplex Strainer Valves Product Specifications

- Valve

- Orange

- High Pressure Pa

- Strainer Valve

- Other

- Water, Gas, Oil, Acid, Base

- Industrial

Duplex Strainer Valves Trade Information

- 5-7 Days

Product Description

Being a reputed entity in this field, we have been engaged in manufacturing and supplying Duplex Strainer Valves to our clients. It is made by utilizing qualitative required yarn with the help of latest techniques. This valve is mainly utilized in piping industries for directing the flow of fluid. All the provided items are properly checked on the various quality parameters before dispatching them from our premises. We offer this Duplex Strainer Valves at common market price rate.

Product details

| Material | Mild Steel |

| Color | Blue |

| Gaskets | SS304 + Grephite Spiral Wounded |

| Model Name/Number | QT-19-DPST |

| Brand | QTC |

| Size/Dimension | 24 inch |

Superior Filtration for Multiple Media

These duplex strainer valves are specially designed to handle a wide variety of process fluids, including water, gas, oil, acid, and base. Their robust build makes them well-suited for high-pressure applications, offering optimum protection for piping and equipment by efficiently removing debris and contaminants before they reach sensitive components.

Built for Industrial Reliability

Our orange-colored duplex strainers are constructed to withstand harsh industrial environments. The duplex design allows operators to switch between two strainer baskets, ensuring continuous operation even during cleaning or maintenance. This minimizes process interruptions and maximizes uptime, essential for critical applications in industry.

FAQ's of Duplex Strainer Valves:

Q: How does a duplex strainer valve work in high-pressure industrial applications?

A: A duplex strainer valve uses two parallel baskets within a single unit, enabling operators to divert flow from one basket to another during cleaning or replacement. This design ensures uninterrupted filtration and continuous operation, which is vital in high-pressure industrial systems handling water, gas, oil, acid, or base.Q: What are the main benefits of using a duplex strainer valve for different media?

A: The primary benefits include consistent filtration, reduced process downtime, and extended equipment life. By efficiently removing contaminants from water, gas, oil, acid, and base, these valves help maintain product purity, protect downstream equipment, and support compliance with industry standards.Q: When is the ideal time to service or clean a duplex strainer valve?

A: Duplex strainer valves are engineered for ease of maintenance, allowing cleaning or basket replacement whenever the pressure drop indicates clogging-without shutting down the system. Regular inspection based on usage and operating conditions ensures optimal performance and longevity.Q: Where can duplex strainer valves be installed in industrial setups?

A: These valves can be integrated at key points in pipelines where continuous filtering of fluids is required, such as before pumps, compressors, or sensitive instrumentation. They are suitable for any industrial plant dealing with high-pressure water, gas, oil, acids, or bases.Q: What is the typical process for switching over baskets in a duplex strainer valve?

A: Operators shift the built-in lever or valve mechanism to divert the flow from the basket being cleaned to the standby basket. This process is quick, safe, and does not interrupt the overall system operation, which is especially valuable in continuous industrial processes.Q: How is the orange coloration of the duplex strainer valves beneficial?

A: The distinctive orange color enhances visibility and safety in industrial environments, making it easier for maintenance personnel to locate the strainer valves among other pipeline components. It also reflects adherence to certain color-coding standards in plant design.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free